The challenge of developing a robust, dexterous and affordable hand was underlined by Tesla-boss Elon Musk, when he spoke at the All-In Summit, external in Los Angeles in September of last year.

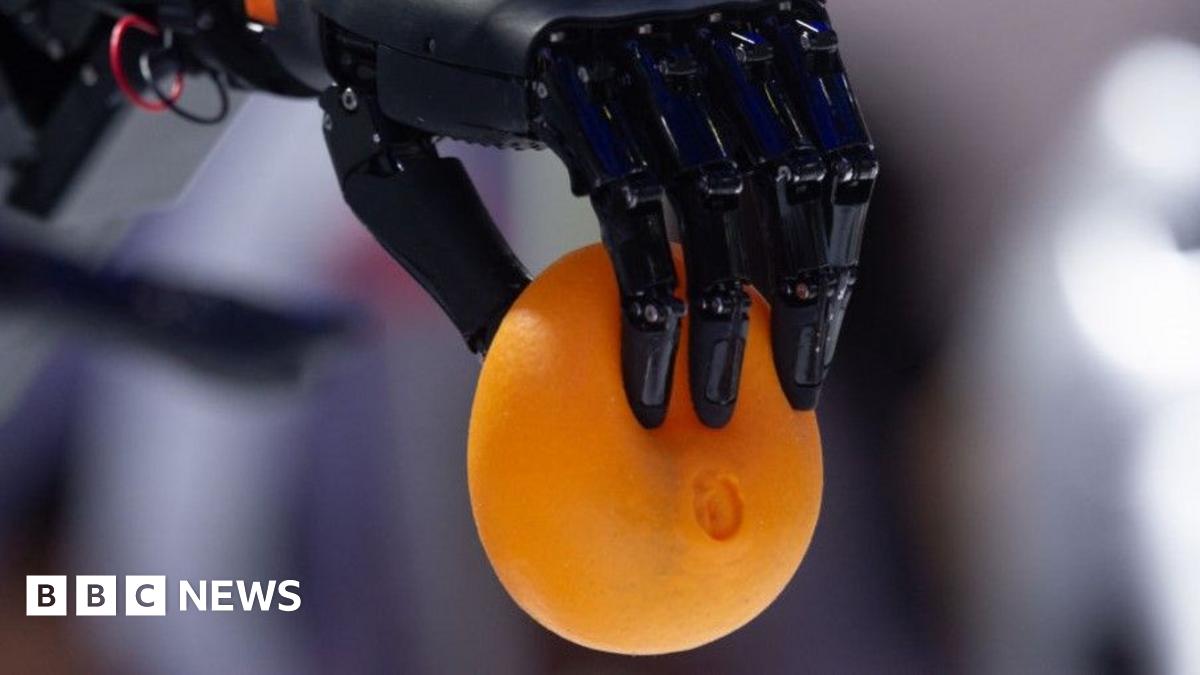

He identified creating a hand as one of the three most difficult problems facing makers of humanoid robotics. The other two were creating an artificial intelligence that allowed the robot to comprehend the world, and making robots in large numbers.

So, a lot of attention will be paid to the latest version of Tesla’s humanoid robot, Optimus, when it is launched this year.

Musk promised it will have “the manual dexterity of a human, meaning a very complex hand”.

“Rubbish,” says Nathan Lepora, Professor of Robotics and AI at Bristol University. He has spent his career working on robot hands and says human level dexterity is still some way off.

“It won’t happen in two years, but we might be talking about 10 years for this to happen, and that’s still a short period of time,” he says.

Lepora is currently working on a robotics project, external under the UK government’s Aria research and development scheme.

Like the Shadow Robot hand, Lepora works on hands with “tendons” that move the fingers.

“Longer-term I think that tendon-driven hands using more sophisticated mechanisms will result in more affordable and capable hands,” he says.

However, he has been impressed with the progress made by Chinese firms who, instead of tendons, are using motors in the fingers and hands to drive movement.

“In China, the people who make motors are getting together with the people who make hand hardware and basically creating bespoke motors that can fit within joints and fingers. It’s probably going to work as an effective hand,” he says.